Advancing Technology: The Impact of Polypropylene Molds in Industry

1. Introduction to Polypropylene Molds

The evolution of manufacturing technologies is pivotal in enhancing production efficiency and reducing costs. Among the various innovations, **polypropylene molds** have emerged as a game-changer in the industry. These molds are not only versatile but also offer significant advantages over traditional materials. As industries strive for greater efficiency and sustainability, understanding the impact of polypropylene molds becomes essential.

2. Understanding Polypropylene: Properties and Benefits

Polypropylene (PP) is a thermoplastic polymer that is widely used in various applications due to its unique properties. It is known for its excellent chemical resistance, low density, and high tensile strength.

2.1. Key Properties of Polypropylene

- **Lightweight**: Polypropylene is approximately 30% lighter than other plastics, making it an ideal choice for applications where weight reduction is crucial.

- **Durability**: Its resistance to impact and fatigue ensures longevity and reliability in products.

- **Thermal Stability**: Polypropylene can withstand high temperatures, making it suitable for various manufacturing processes.

2.2. Benefits of Polypropylene Molds

The benefits of using polypropylene molds include:

- **Cost-Effective**: Lower material costs and reduced manufacturing time lead to overall cost savings.

- **Versatile Applications**: From automotive components to consumer goods, polypropylene molds can adapt to various industries.

- **Ease of Processing**: Polypropylene can be easily molded and shaped, allowing for complex designs and quick production cycles.

3. Applications of Polypropylene Molds in Various Industries

Polypropylene molds are utilized across a wide range of industries, each benefiting from their specific properties.

3.1. Automotive Industry

In the automotive sector, polypropylene molds are employed to produce lightweight components that enhance fuel efficiency. Parts such as dashboards, bumpers, and interior trims leverage the lightweight nature of polypropylene.

3.2. Consumer Products

The consumer goods industry uses polypropylene molds for packaging, containers, and household items. The material's durability and chemical resistance make it ideal for products that require frequent handling.

3.3. Medical Devices

In the healthcare sector, polypropylene molds are essential for manufacturing disposable medical devices. Their ability to withstand sterilization processes ensures product safety and reliability.

4. Advantages of Using Polypropylene Molds

Utilizing polypropylene molds presents several advantages that can significantly impact production efficiency and product quality.

4.1. Enhanced Design Flexibility

Polypropylene molds allow for intricate designs that traditional materials cannot accommodate. This flexibility paves the way for innovation in product design.

4.2. Reduced Production Costs

By minimizing cycle times and material waste, polypropylene molds contribute to overall cost reductions. This efficiency translates into better profit margins for manufacturers.

4.3. Improved Quality Control

The consistency in molding processes ensures high-quality outputs. Manufacturers can maintain stringent quality standards, which enhances customer satisfaction.

5. Manufacturing Techniques for Polypropylene Molds

The production of polypropylene molds involves advanced manufacturing techniques that maximize efficiency and precision.

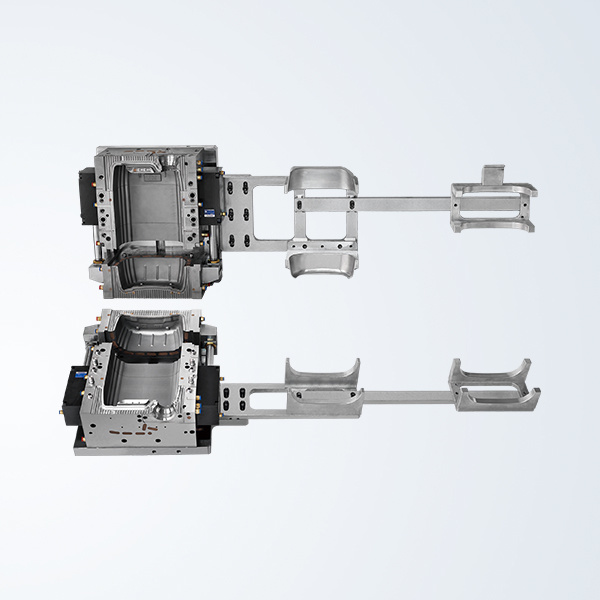

5.1. Injection Molding

Injection molding is a prevalent technique for creating polypropylene molds. The process involves injecting molten polypropylene into a mold cavity, where it cools and solidifies into the desired shape.

5.2. Blow Molding

Blow molding is utilized for creating hollow polypropylene products, such as bottles. This method allows manufacturers to produce lightweight and durable containers efficiently.

5.3. Thermoforming

Thermoforming involves heating a sheet of polypropylene until pliable and then shaping it into a mold. This technique is particularly useful for larger items with shallow depths.

6. Environmental Impact and Sustainability of Polypropylene Molds

As industries seek sustainable solutions, polypropylene molds present an opportunity for eco-friendly manufacturing.

6.1. Recyclability of Polypropylene

Polypropylene is 100% recyclable, which reduces waste in the manufacturing process. Recycled polypropylene can be used to create new molds, promoting a circular economy.

6.2. Energy Efficiency

The production of polypropylene molds often requires less energy compared to other materials, contributing to lower carbon emissions during manufacturing.

7. Future Trends in Polypropylene Mold Technology

The landscape of polypropylene mold technology is continuously evolving. Key trends shaping the future include:

7.1. Smart Manufacturing

Integrating smart technology into mold manufacturing processes can enhance precision and efficiency. Automation and IoT (Internet of Things) will play critical roles in optimizing production.

7.2. Biopolymers and Sustainable Alternatives

As sustainability becomes a priority, the development of biopolymers that mimic polypropylene properties is on the rise. These materials could offer environmentally friendly alternatives to traditional polypropylene.

评论

发表评论