How a CNC Lathe with Bar Feeder Transforms Production

1. Introduction to CNC Lathes and Bar Feeders

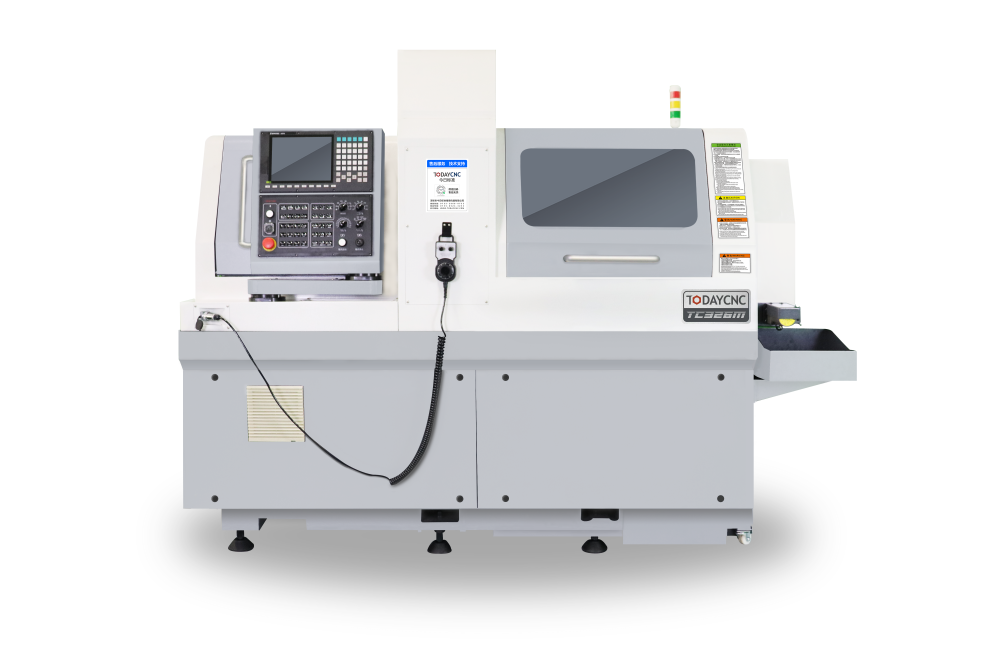

The manufacturing industry is constantly evolving, adopting new technologies to enhance efficiency and productivity. Among these innovations, the integration of **CNC lathe with bar feeders** stands out as a transformative solution. This combination not only maximizes production output but also streamlines processes to ensure unmatched precision and reliability in machining operations.

2. Understanding CNC Technology

CNC technology has revolutionized the way we approach machining. By employing advanced software and machinery, it allows for automated control of machining tools, resulting in increased accuracy and efficiency.

2.1 What is CNC (Computer Numerical Control)?

CNC, or **Computer Numerical Control**, refers to the automation of machine tools via computers executing pre-programmed sequences. This technology enables operators to produce complex parts with minimal manual intervention.

2.2 Advantages of CNC Machining

CNC machining offers several advantages, including:

- **High Precision:** CNC machines can produce parts with incredibly tight tolerances.

- **Repeatability:** Once programmed, CNC machines can consistently replicate parts without variance.

- **Complex Geometries:** CNC lathes can create intricate shapes that would be difficult or impossible with manual machining.

3. The Role of Bar Feeders in CNC Lathes

Bar feeders play a critical role in enhancing the capabilities of CNC lathes, allowing for continuous production with minimal downtime.

3.1 What is a Bar Feeder?

A **bar feeder** is a device that automatically loads raw material into a CNC lathe. This ensures that the lathe is continuously supplied with material, enabling it to operate efficiently without interruptions.

3.2 Types of Bar Feeders

Bar feeders come in various types, including:

- **Hydraulic Bar Feeders:** These use hydraulic power to feed bars into the lathe.

- **Mechanical Bar Feeders:** These manually push bars through the lathe.

- **Servo Bar Feeders:** These employ servo motors for precise control of feeding speed and accuracy.

4. How a CNC Lathe with Bar Feeder Boosts Productivity

Combining a CNC lathe with a bar feeder can significantly enhance production capabilities.

4.1 Automation and Reduced Labor Costs

The integration of a bar feeder allows for unattended operation, meaning a lathe can run for hours or even days without needing human intervention. This automation leads to substantial labor cost savings and enables manufacturers to allocate human resources more efficiently.

4.2 Increased Precision and Accuracy

CNC lathes equipped with bar feeders ensure that every piece of raw material is processed uniformly. This consistency results in high-quality outputs that meet stringent industry standards, reducing waste and the need for rework.

5. Key Features of CNC Lathes with Bar Feeders

When evaluating CNC lathes with bar feeders, several key features contribute to their effectiveness:

5.1 Programming Capabilities

Modern CNC lathes come with advanced programming interfaces that allow for easy modifications and updates to machining processes. This flexibility ensures quicker adjustments to changing production requirements.

5.2 Enhanced Cycle Times

CNC lathes with integrated bar feeders can dramatically reduce cycle times. Since the bar feeder continuously supplies material, the lathe spends less time in downtime, significantly increasing throughput.

6. Industries Benefiting from CNC Lathes with Bar Feeders

Many industries have embraced the use of CNC lathes with bar feeders, including:

- **Automotive Manufacturing:** For producing precision components such as shafts and bolts.

- **Aerospace:** Where high tolerances and reliability are critical.

- **Medical Device Manufacturing:** For crafting intricate parts that require strict regulatory compliance.

7. Considerations for Implementing CNC Lathes with Bar Feeders

While the benefits of CNC lathes with bar feeders are clear, potential adopters should consider several factors:

7.1 Initial Investment vs. Long-term Gains

Investing in CNC technology requires significant upfront costs, including equipment, software, and training. However, the long-term gains in productivity and efficiency often outweigh these initial expenses.

7.2 Maintenance and Support

Proper maintenance is crucial for maximizing the lifespan of CNC machines and bar feeders. Regular servicing and support from manufacturers ensure machines remain in optimal working condition.

8. Future Trends in CNC Machining and Bar Feeding

The future of CNC machining and bar feeding technology looks promising. Developments in **artificial intelligence**, **machine learning**, and **IoT (Internet of Things)** are expected to further enhance efficiency, enabling even smarter and more adaptive manufacturing processes.

评论

发表评论