Understanding the Benefits and Functionality of Standing Seam Metal Roofing Machines

Standing seam metal roofing machines are essential tools in the metal processing sector, particularly for manufacturers focused on producing high-quality roofing panels. These machines are designed to create standing seam roof panels, which are known for their durability, weather resistance, and aesthetic appeal. Standing seam roofs consist of vertical panels with raised seams that interlock, providing a distinctive appearance while offering superior protection from the elements.

One of the primary benefits of standing seam metal roofing machines is their ability to produce panels that require minimal maintenance and have a long lifespan. The interlocking design minimizes the potential for leaks, as water is directed away from seams, making these roofs ideal for various climates. Additionally, the materials used in these roofs are often recyclable, promoting sustainability within the construction industry.

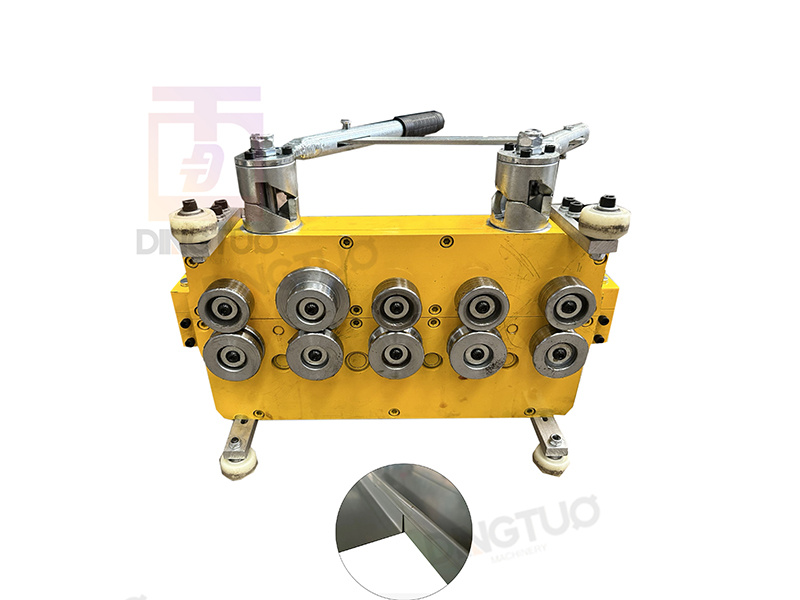

The operation of a standing seam metal roofing machine involves several key processes. Initially, metal sheets are fed into the machine, where they are shaped and formed into panels. The machine is equipped with various rollers and dies that create the necessary folds and seams. Advanced machines may also include features for adding finishes or coatings, enhancing the panels' resistance to corrosion and UV damage.

In terms of applications, standing seam metal roofing is widely used in both residential and commercial structures. Its versatility allows it to be installed on a variety of roof pitches, making it suitable for different architectural styles. Additionally, the energy efficiency of standing seam roofs is noteworthy; many designs include insulation options that enhance thermal performance, leading to reduced energy costs over time.

Moreover, the investment in a standing seam metal roofing machine can lead to significant cost savings for manufacturers. By streamlining the production process and ensuring high-quality output, these machines enable businesses to meet market demands efficiently. As demand for metal roofing continues to rise, particularly in green building projects, the relevance of standing seam metal roofing machines only increases.

In conclusion, standing seam metal roofing machines play a crucial role in modern manufacturing processes within the metal processing industry. Understanding their functionality and benefits can help businesses decide on the best equipment for their production needs. By leveraging these machines, manufacturers can enhance their product offerings and contribute to sustainable building practices, ensuring they remain competitive in a rapidly evolving market.

评论

发表评论