Maximize Efficiency: How a Durable High Pressure Water Pump Transforms Your Workflow

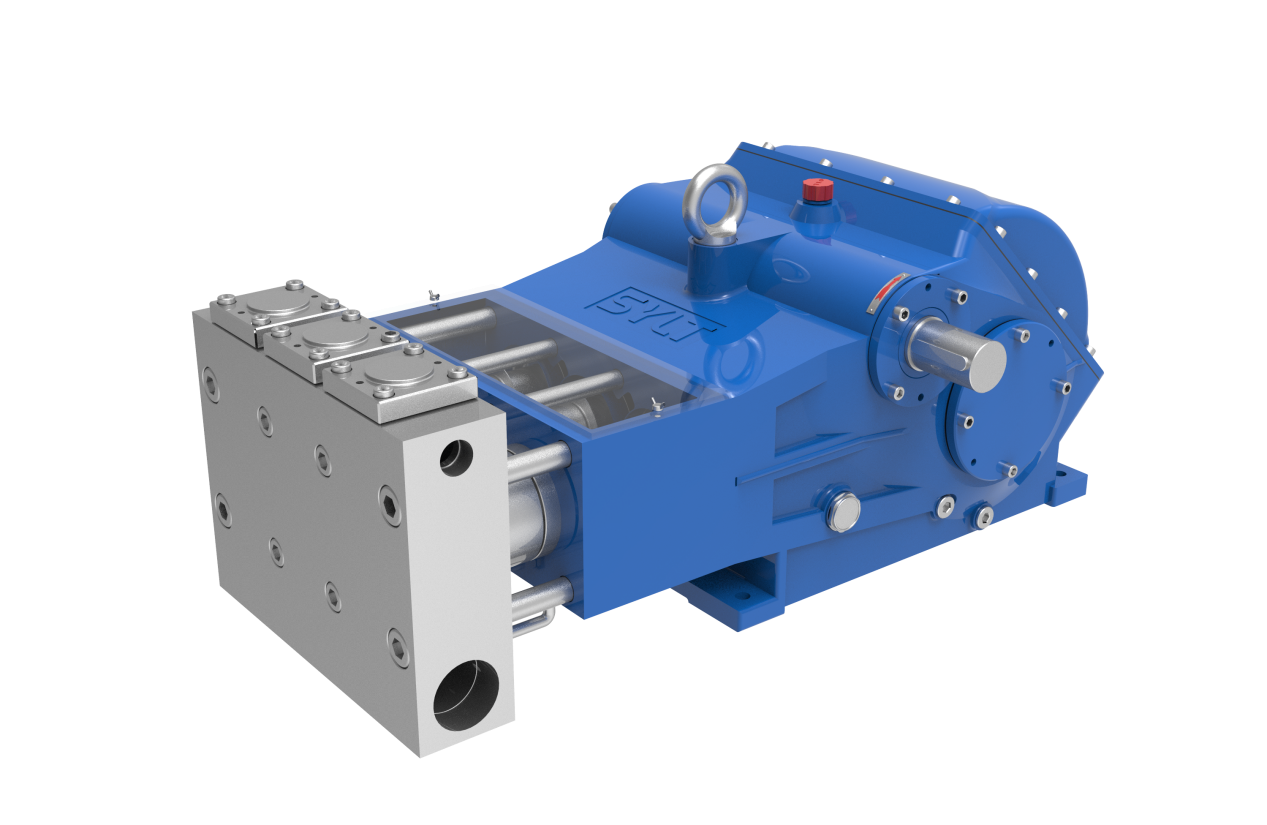

Types of High Pressure Water Pumps

The Importance of Durability in Industrial Pumps

Durability is a critical factor when selecting a high-pressure water pump. **Industrial environments** are often harsh, subjecting equipment to extreme temperatures, corrosive substances, and heavy usage. A durable pump minimizes the risk of breakdowns and extends the lifespan of the equipment, translating into significant cost savings over time.

Material Considerations

The materials used in the construction of high-pressure water pumps play a vital role in their durability. Common materials include:

- **Stainless Steel**: Resistant to corrosion and wear, suitable for various applications.

- **Cast Iron**: Offers strength and stability, often used in heavy-duty pumps.

- **Thermoplastics**: Lightweight and resistant to corrosion, ideal for chemical handling.

Selecting the right material based on the application can enhance pump longevity and performance.

Benefits of High Pressure Water Pumps in Various Industries

High pressure water pumps offer numerous advantages across various sectors:

1. Enhanced Cleaning Capabilities

In industries like manufacturing and food processing, high-pressure water pumps are essential for effective cleaning. The force generated by these pumps can remove dirt, grease, and other contaminants, ensuring compliance with health and safety regulations.

2. Increased Production Efficiency

High-pressure pumps can optimize production processes by delivering water and fluids at precisely the required pressure. This capability reduces downtime and boosts overall efficiency, enabling businesses to meet production targets more effectively.

3. Versatile Applications

From powering hydraulic equipment to facilitating irrigation systems, high-pressure water pumps are versatile tools that can adapt to various industrial needs. This flexibility allows companies to streamline operations and reduce the need for multiple types of equipment.

4. Energy Savings

With advancements in technology, modern high pressure water pumps are designed to be more energy-efficient. This efficiency translates to lower operational costs and a reduced carbon footprint, making them an environmentally friendly choice for businesses.

How High Pressure Water Pumps Maximize Efficiency

Maximizing efficiency with high-pressure water pumps involves various strategies:

1. Optimal Sizing and Selection

Choosing the right pump size and type for your application is crucial. An oversized pump can lead to excessive energy consumption, while an undersized pump may not meet operational demands. Conducting a thorough analysis of your needs ensures optimal performance.

2. Regular Monitoring and Adjustments

Implementing monitoring systems can provide real-time data on pump performance, allowing for timely adjustments. This practice prevents potential issues before they escalate, ensuring continuous operation.

3. Automation Integration

Integrating high-pressure pumps with automated systems can enhance precision and reduce human error. Automation allows for consistent performance, further improving overall efficiency.

Installation and Setup Guidelines

Proper installation and setup are essential for ensuring the longevity and efficiency of high-pressure water pumps. Here are some key considerations:

1. Site Assessment

Before installation, conduct a thorough site assessment to understand environmental conditions and requirements. This step will inform pump selection and placement.

2. Follow Manufacturer Instructions

Always adhere to the manufacturer's installation guidelines. This practice helps avoid operational issues and ensures the pump operates within its recommended parameters.

3. Ensure Proper Connections

Check all connections for leaks and secure fittings. Proper connections are vital for maintaining pressure and preventing fluid loss.

Maintenance Best Practices for Longevity

To maximize the lifespan and efficiency of high-pressure water pumps, implement these maintenance best practices:

1. Regular Inspections

Conduct regular inspections to identify wear and tear before they become significant issues. Look for signs of leaks, unusual noises, or vibrations.

2. Clean Filters and Strainers

Keeping filters and strainers clean ensures optimal flow and prevents debris from damaging internal components. Schedule regular cleaning based on usage frequency.

3. Lubrication

Proper lubrication of moving parts reduces friction and wear. Follow the manufacturer’s recommendations for lubrication frequency and type.

Common Issues and Solutions for High Pressure Water Pumps

High-pressure water pumps can encounter several common issues:

1. Low Pressure

If the pump is not delivering adequate pressure, check for blockages in the intake line or filter. Ensure that the pump is correctly sized for the application.

2. Overheating

Overheating can result from insufficient cooling or excessive workload. Ensure that the pump is operating within its specified limits and that cooling systems are functioning correctly.

3. Leakage

Leaks often occur at seals or connections. Regularly inspect and replace worn seals and ensure all connections are tight.

Conclusion

Investing in a **durable high-pressure water pump** can significantly transform your workflow by enhancing efficiency, reducing downtime, and increasing productivity. Understanding the features, benefits, and maintenance practices associated with these pumps is essential for optimizing their performance. By implementing the strategies outlined in this article, you can ensure that your high-pressure water pump serves your industrial needs effectively and efficiently.

评论

发表评论