Unlocking High Efficiency: The Magic of Fancy High Flow High Pressure Pumps

1. Introduction to High Flow High Pressure Pumps

2. Understanding the Technology Behind High Flow High Pressure Pumps

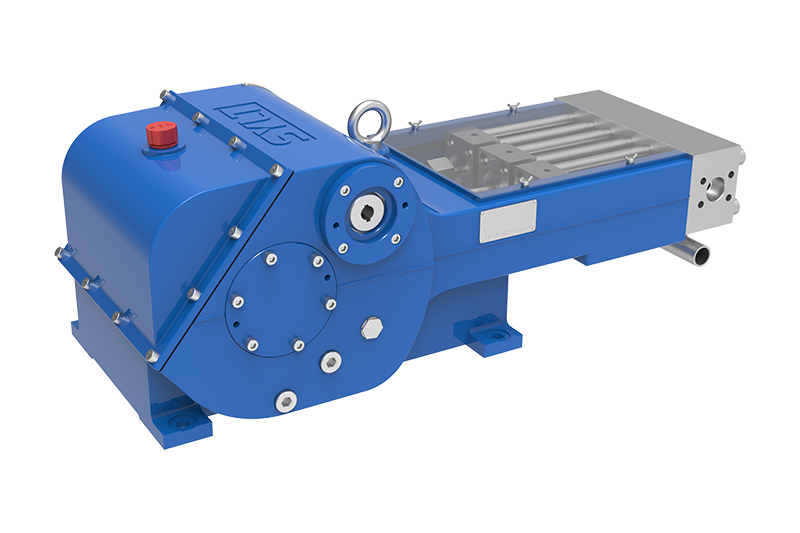

The technology that underpins the **high flow high pressure pump** is both intricate and fascinating. These pumps utilize various mechanisms, such as positive displacement and centrifugal designs, to achieve high efficiency in fluid movement.

2.1 Positive Displacement Pumps

Positive displacement pumps function by trapping a fixed amount of fluid and forcing it through the pump’s outlet. This design ensures that fluid flow is consistent, regardless of pressure variations in the system, making them ideal for high-pressure applications.

2.2 Centrifugal Pumps

Centrifugal pumps use rotational energy to move fluid through the pump. They are highly efficient at transporting large volumes of fluids and are widely used in various industrial processes. Their design allows for high flow rates, making them perfect for applications where speed and volume are critical.

3. Key Benefits of High Flow High Pressure Pumps

Investing in high flow high pressure pumps offers numerous benefits:

3.1 Increased Efficiency

3.2 Versatility

High flow high pressure pumps can handle a variety of fluids, including corrosive materials, making them suitable for diverse industries such as chemical manufacturing, waste management, and agriculture.

3.3 Improved Productivity

By enabling faster fluid transfer, these pumps significantly boost productivity. This is particularly beneficial in processes that require rapid fluid movement, such as in construction or mining operations.

4. Applications of High Flow High Pressure Pumps Across Industries

The versatility of high flow high pressure pumps is evident in their wide-ranging applications:

4.1 Water Treatment

In water treatment facilities, these pumps are essential for transporting and treating large volumes of water, ensuring safe and efficient processing.

4.2 Oil and Gas

In the oil and gas industry, high flow pumps are utilized for transporting crude oil and other fluids under high pressure, ensuring seamless operations.

4.3 Chemical Processing

Chemical manufacturers rely on high flow high pressure pumps to handle various chemicals, facilitating efficient mixing, transportation, and storage.

4.4 Food and Beverage Industry

In the food and beverage sector, these pumps ensure hygienic transport of liquids, such as juices and sauces, maintaining product integrity.

5. Criteria for Selecting the Right High Flow High Pressure Pump

Choosing the appropriate pump is crucial for maximizing efficiency and productivity. Consider the following factors:

5.1 Flow Rate Requirements

Assess the required flow rate for your application to determine the pump size and type that will meet your needs effectively.

5.2 Pressure Specifications

Understanding the pressure requirements of your process is vital to selecting a pump capable of delivering the necessary pressure without compromising performance.

5.3 Fluid Characteristics

Analyze the properties of the fluid being pumped, including viscosity, temperature, and corrosiveness, to choose a pump that will withstand the operational conditions.

6. Maintenance Tips for High Flow High Pressure Pumps

Regular maintenance is essential to ensure the longevity and efficiency of high flow high pressure pumps:

6.1 Routine Inspections

Conduct regular inspections to identify any signs of wear and tear, ensuring timely repairs to avoid operational disruptions.

6.2 Lubrication

Proper lubrication of moving parts reduces friction and wear, enhancing pump performance and extending its lifespan.

6.3 Replacement of Worn Parts

Replace worn parts promptly to prevent pump failure and maintain operational efficiency.

7. Case Studies: Success Stories Using High Flow High Pressure Pumps

Real-world applications highlight the role of high flow high pressure pumps in achieving operational excellence. Here are a few notable examples:

7.1 Water Treatment Facility in California

A large water treatment facility in California implemented high flow high pressure pumps to enhance water processing efficiency, resulting in a 30% reduction in energy costs.

7.2 Oil Extraction Operation in Texas

In Texas, an oil extraction company adopted high flow high pressure pumps to streamline crude oil transportation, improving production rates by 25%.

8. Future Trends in Pump Technology and Efficiency

The future of high flow high pressure pumps is promising as technology evolves. Key trends include:

8.1 Smart Pump Technology

The integration of IoT technology into pumps allows for real-time monitoring and predictive maintenance, enhancing operational efficiency and reducing downtime.

8.2 Energy Efficiency Standards

As industries become more environmentally conscious, the push for energy-efficient pumps is increasing, driving innovation in pump design and technology.

8.3 Advanced Materials

The development of advanced materials will improve pump durability and performance, especially in challenging environments.

评论

发表评论